Induction hardening

Our hardening solutions are used by many of the world’s leading car manufacturers and their suppliers.

What is induction hardening?

What are the benefits?

- A fast and repeatable process that integrates easily into production lines

- Clean, safe, energy-efficient, and typically with a small footprint

- Individually treated workpieces; each piece is hardened to its precise specification

Where is it used?

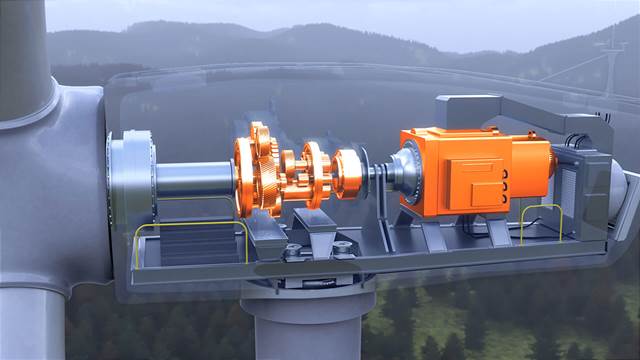

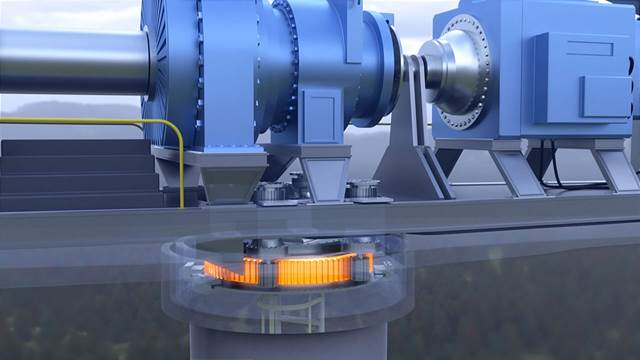

Induction is used to harden numerous components. Here are just a few of them: gears, crankshafts, camshafts, drive shafts, output shafts, torsion bars, rocker arms, CV joints, tulips, valves, rock drills, and slewing rings, as well as inner and outer races.

ENRX hardening solutions are utilized across a wide range of industries globally. However, most systems fall into the following categories.

What equipment is available?

Solutions explained

Insights and resources

Download brochures and expert materials on induction heating technologies and their industrial applications.

Induction heating applications | Processes, equipment and benefits

Discover how ENRX induction heating improves efficiency, precision, and sustainability across industrial applications — from brazing and bonding to forging and annealing. Learn about the processes, equipment, and benefits of modern induction technology.