HardLine: Induction hardening machines

A complete range of stationary systems for all types of workpieces requiring hardening, tempering and annealing.

Introduction

HardLine is our family of heat treatment systems for surface and through hardening. It is a comprehensive, versatile range that includes induction hardening systems for every hardening job. HardLine includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. From small, manually loaded machines to large, automatic turnkey hardening plants complete with component handling, washing, straightening, and tempering capabilities.

Learn about how and where the HardLine family can be used

RELATED APPLICATIONS

related industries

The HardLine family

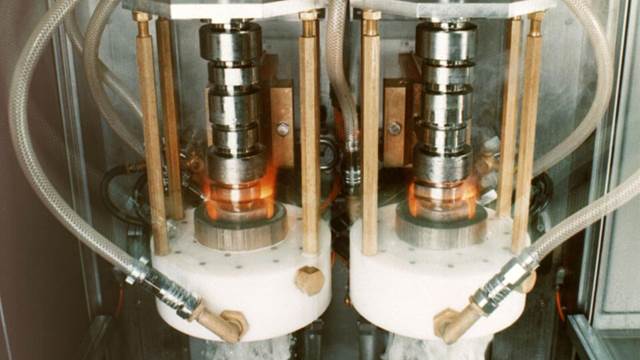

Using modules with proven high-quality components, the modular machines can be customised for different hardening and annealing applications, providing maximum flexibility and long-term operation at low cost. Ergonomic design, easy access to cooling water components and a limited variety of spare part types also makes every modular machine easy to maintain.

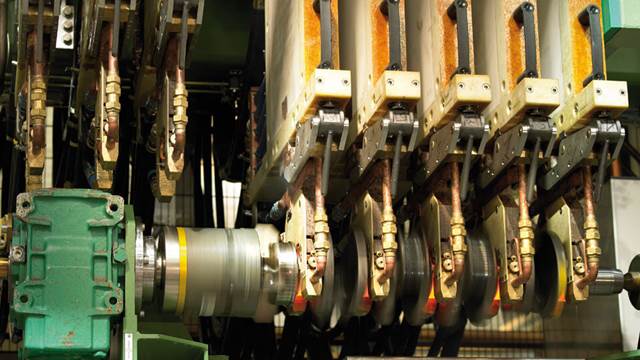

ENRX’s modular system can deliver horizontal pusher-feed, continuous-feed or hybrid machines with pusher and continuous in one framework. All our horizontal machines are powered by Sinac converters.

Our versatile vertical machines cover everything from manually loaded to fully automated in-line systems. Different models are available for hardening workpieces in sizes ranging from small components to large dimension rollers.

The parallel loading/hardening capability of our rotary table machines makes them ideal for minimizing cycle times in high-volume production. High throughput, low capital costs, and ergonomic design for operator productivity. Throughput rates can be further increased by adding extra stations.

We have a system for every type of crankshaft – be it marine, compressor, car, truck, or anything else – at any production volume. We offer robot-loaded machines as well as drum and single-station models for large crankshafts. We also offer walking beam and chain conveyor machines with a capacity of 1-4 stations.

Nearly half of our hardening machines are custom-engineered systems. One specialty is the design and production of laser hardening and drum (Trunion) systems. We also help with in-line transfer and conveyor systems for complex components with multiple hardening and tempering zones.

Our Energy Management System identifies your peak energy consumption weak spots. At a glance, you will be able to see where action needs to be taken, and you can easily calculate your long-term savings.