Induction heating applications

From faucets to spaceships, from solar cells to bulldozers, from wind farms to power stations. Induction heating can be used in a wide variety of industrial applications.

View all applications

Annealing and normalising

Induction heating for treating individual workpieces to exact specifications.

Bolt heating

Induction heating for fast and easy bolt expansion in high-pressure turbines.

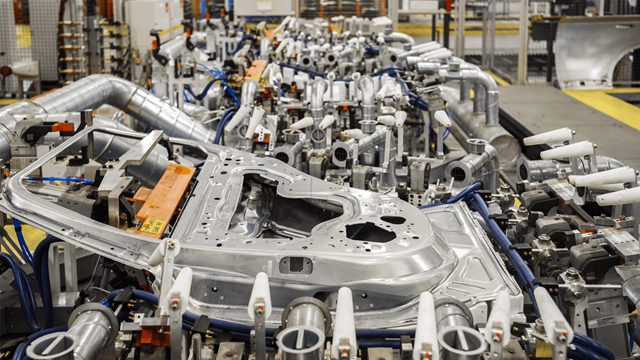

Bonding

Induction heating for the bonding of adhesives and sealants for components.

Brazing

Induction heating for joining a wide range of metals, even ferrous to non-ferrous.

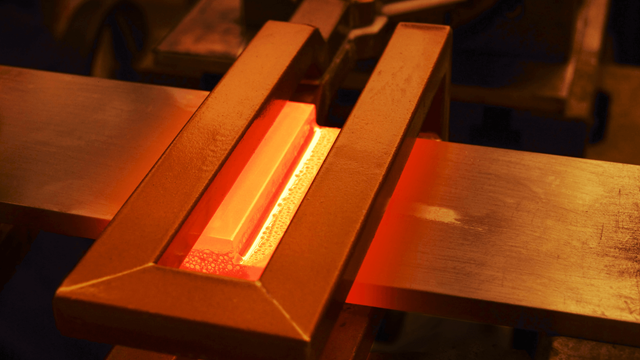

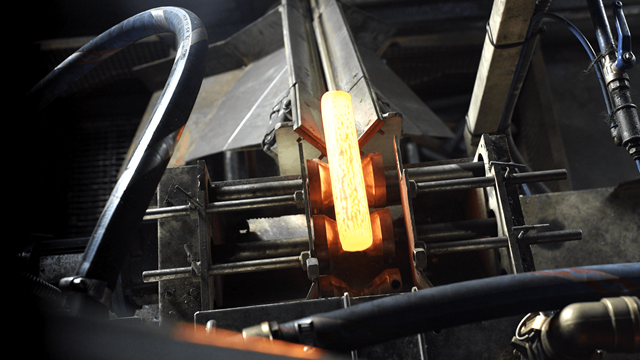

Forging

Induction heating of metal parts before shaping by presses or hammers.

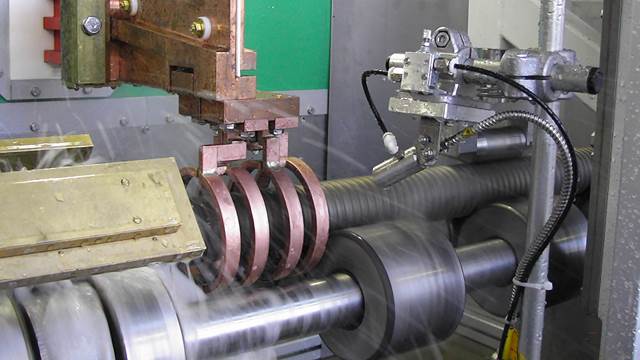

Hardening

Induction heating for increasing the hardness and durability of steel.

Melting

Induction heating for the melting of metal and glass into liquid form.

Paint and coating removal

Induction heating cutting coating removal times by up to 90 percent.

Post-heating

Induction heating for the post-treatment of materials and workpieces.

Pre-heating

Induction heating of materials and workpieces prior to further processing.

Shrink fitting

Induction heating for temporary expansion for insertion or removal of parts.

Straightening

Induction heating cutting deck straightening times by up to 80 percent.

Tempering

Induction heating for optimizing mechanical properties in hardened workpieces.

Welding

Induction heating to ensure reliable and high-throughput longitudinal welding.

Wire and cable heating

Induction heating for the manufacturing and processing of wire and cable products.