Consumables

Keep up performance and reduce the risk of breakdowns within tube and pipe welding.

Introduction

With specific expertise in the high frequency (HF) welding process, we offer a full range of products to help you maintain or even improve your productivity. We can provide everything from strip edge conditioning through to the welding process itself and final OD/ID removal of welding flash.

- Improve your production

- Reduce your operating costs

- Increase your efficiency

Learn about how and where consumables can be used

We manufacture induction coils made with high conductivity copper for all kinds of HF generators that fit all well-known industry brands. We also offer a special coating process for contact surfaces on the coil which reduces oxidization that can lead to resistance on coil connection.

- Banded coils

- Coil holders and busbars

- Large diameter coils

- Profile coils

- Tubular coils

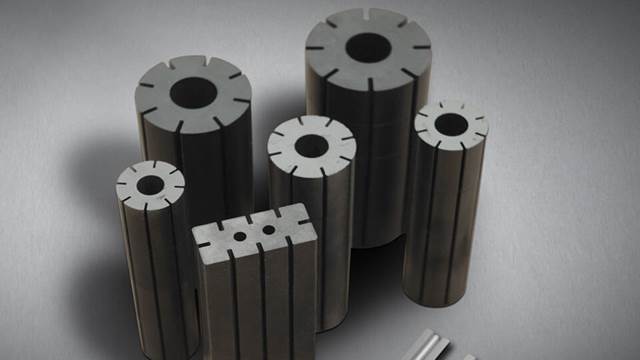

Impeders are an integral and critical component in the pipe welding process. Often neglected, they can cost your business substantial amounts of money every year if they are not properly designed, manufactured and correctly selected. Our impeders have the highest quality ferrite grade, protected by the best available casings.

- Hollow/ID scarfing impeders

- Impeder fixing systems

- Large diameter impeders

- Profile impeders

- Return flow impeders

- Through flow impeders

We offer a wide range of impeder casing sizes and materials. We have a solution for every HF welding application.

- Epoxy glass – high-density filament wound

- Ferroglass – ferrite powder impregnated glass

- Silglass – silicone resin bonded glass

- Weld guard – S300WG

Our pump and filter systems ensure clean high-pressure coolant is delivered to the impeder and induction coil. The result: Higher efficiency, more uptime and increased component life.

- CS-1C – suitable for smaller impeders (up to 28 mm through flow/return flow)

- CS-2 – suitable for larger impeders (up to 89 mm through flow/return flow)

Evolgy offers a range of equipment and consumables for scarfing. This encompasses Canticut ID scarfing systems, Duratrim edge conditioning units and a full range of high quality scarfing inserts and associated tooling.

- Canticut – a unique cantilever ID scarfing system

- Duratrim – edge scarfing system for welded tube mills

- ID inserts and cutting rings, and ID tool holders

- Tool holders and accessories