Induction brazing

ENRX offers brazing in various fields, such as the automotive, aviation, electrotechnical and white goods industries.

What is induction brazing?

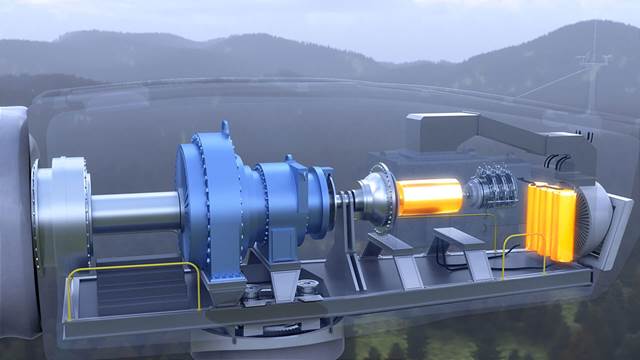

Brazing is a materials joining process that uses a filler metal (and usually an anti-oxidizing solvent called flux) to join two pieces of close-fitting metal together without melting the base materials. Instead, induced heat melts the filler, which is then drawn into the base materials by capillary action.

What are the benefits?

- Join a wide range of metals, even ferrous to non-ferrous

- Heat only narrowly defined areas

- Ideal for integration into production lines

- Correctly brazed joints are strong, leakproof and corrosion resistant

- They are also very neat, usually requiring no further milling, grinding or finishing

Where is it used?

What equipment is available?

Solutions explained

Insights and resources

Download brochures and expert materials on induction heating technologies and their industrial applications.

Induction brazing solutions | Fast, precise and reliable

Discover ENRX induction brazing systems for fast, precise and repeatable metal joining. Ideal for HVAC, automotive, electrotechnical and industrial applications.

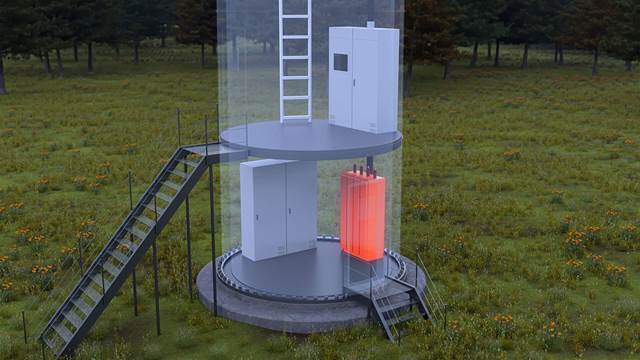

ENRX Minac® | Mobile induction heating equipment

You can move your Minac® around a workshop or factory floor or easily load it into a car and transport it to work sites. It can be fitted with a practically limitless range of coil designs and coil fixtures, flexible cables, closed or separate cooling systems, specially designed heating cables, etc.

ENRX Sinac® | Stationary induction heating systems for maximum efficiency

Discover ENRX Sinac®, the complete range of stationary induction heating systems for precision, energy efficiency, and durability. Designed for applications like brazing, bonding, hardening, and shrink-fitting, Sinac ensures optimal heating performance across automotive, electrotechnical, and renewable industries

Induction heating applications | Processes, equipment and benefits

Discover how ENRX induction heating improves efficiency, precision, and sustainability across industrial applications — from brazing and bonding to forging and annealing. Learn about the processes, equipment, and benefits of modern induction technology.